Advanced technology

Photonics integrated circuits (PICs) are now extensively installed in several technological fields and application markets. Telecommaunications, data centers, life science, quantum computing, sensing, and imaging are just a few examples a PICs bring benefits in system size, power consumption, and operational costs.

Novel technologies

Several material platforms can support PICs, such as Silicon, Silicon Nitride, or InP, yet no single platform succeeds in combining all their respective advantages. As heterogeneous integration and co-packaging approaches rise as mainstream manufacturing paradigms, their large entry cost barriers confine them to restricted high-volume application markets.

AEPONYX pioneers the industrialization of novel technologies such as Photonic Wire Bonding to improve the manufacturability and cost-effectiveness of long-proven hybrid integration technologies for medium to high-volume application markets.

Silicon nitride photonics

Silicon nitride photonics is certainly the most versatile platform thanks to its wide wavelength range, 450 nm to 2350 nm, over which it maintains low optical losses, thermal stability, and the ability to handle high optical power densities.

AEPONYX is proud to offer a PIC platform combining the benefits of SiN waveguides and of micro-electro-mechanical systems (MEMS) fabrication processes out of two different MEMS foundries. Our proprietary photonic MEMS process allows for power-effective, high-speed optical switching and thermal tuning thanks to suspended membranes and deep cavities that lowear the thermal mass of photonics circuits. AEPONYX possesses the expertise to design photonic circuits, develop their fabrication process, ramp them up for production, and operate them in a fabless scheme.

While SiN does not sustain active devices like Si and InP do, our robust manufacturing process flows allow the fabrication of versatile mechanical structures that facilitate the integration of foreign active or passive discreet optical devices directly into our PICs to provide self-contained and compact monolithic optical engines.

High-output power light sources, burst-capable lasers, high-gain SOAs, LNO-based phase modulators, and many more can thus be inserted directly into the SiN waveguide paths in low-insertion loss and polarization-maintaining schemes.

This approach competes advantageously against processes resorting to direct wafer bonding or heterogeneous epitaxial growth of semiconductors, as it brings more flexibility in component characteristics selection and better backward compatibility to existing integrations. Therefore, high-performance devices can be integrated with complex photonic functionalities such as polarization splitting, spectral filtering, and optical routing without resorting to free space optics.

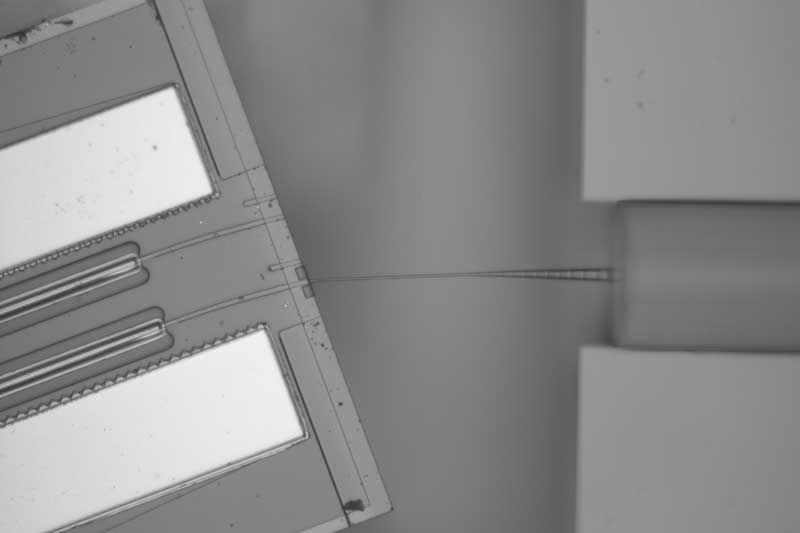

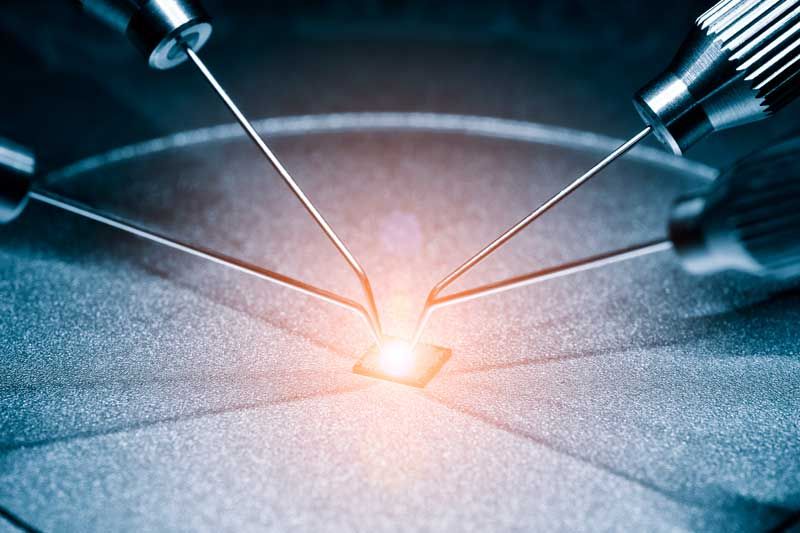

Photonic wire bonding

AEPONYX circumvents the widely decried and costly active alignment steps associated with hybrid integration using Photonic Wire Bonding. This rising technology allows direct and self-aligned writing of waveguides that perform mode field matching between devices with sometimes largely differing mode sizes.

This production-friendly process allows the direct implementation of optical coupling links at wafer and single-device levels. It allows leveraging the technological maturity of long-proven hybrid integration techniques while reducing costs to bring fast time-to-market and little to no integration compromise.

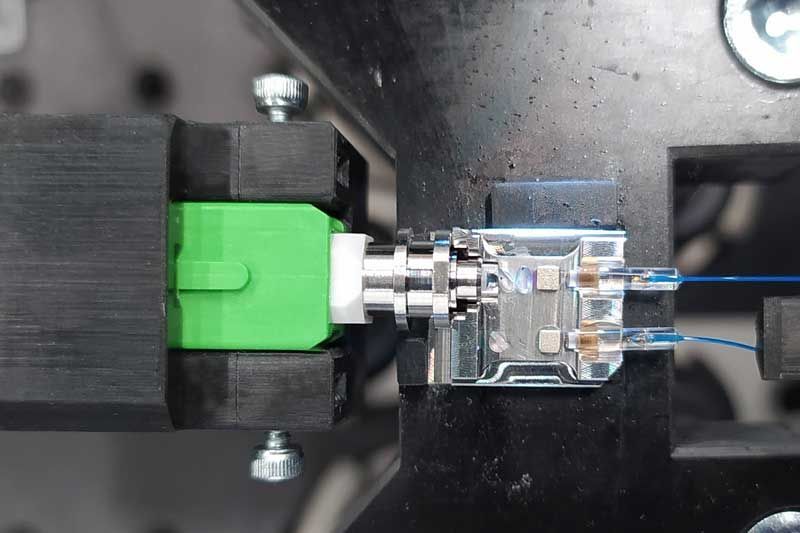

Free-space world

Elements like isolators, circulators, frequency doublers, fine-resolution filters, and many other components are still unavailable as reliable PIC components. Although Photonic Wire Bonding is our go-to technique, AEPONYX acknowledges the need to use traditional free-space coupling to devices when required. We have therefore developed the expertise to design and fabricate optical benches that couple foreign devices with PICs in both manual or automated processes for rapid prototyping or mass production.

AEPONYX made an exciting breakthrough, innovating recently how one can integrate optical isolators directly into PICs with minimum insertion loss and appealing isolation ratios. Stay tuned as more details will soon become available.

System integration

Beyond photonics and optics, AEPONYX has become a one-stop shop for optical engine vertical integration. Over the last 5 years, we have developed a comprehensive portfolio of technological blocks in electronics design (power distribution, logic control, and RF signal processing), active thermal stabilization, thermo-optical compensation, mechanical and optoelectronic packaging, design for testability, design for manufacturability and more.

As such, we can handle any integrated photonics product’s journey from design to production.

Eyes on the future

AEPONYX is now adapting its technological portfolio to serve ambitious markets beyond telecom/datacom, such as next-generations quantum computers, quantum and bio-photonic sensors, as well as systems.

Quantum technologies are shifting away from research and development towards engineering and commercialization. This shift requires the mastering of several hardware disciplines in addition to quantum physics: photonics, mechanical, electrical, thermal and vacuum management. PICs are increasingly recognized as the most viable path to miniaturizing and crunching the cost structure of quantum systems while improving their stability.

Optical transduction is one of the most sensitive methods, Mach-Zehnder interferometers being perhaps the most sensitive photonic device out there. Many bio-sensing applications can benefit from our innovative integration approaches to quickly reach the market, from advanced outbreak detection in public wastewater to food industry monitoring.

Working with a skilled PIC partner capable of engineering and manufacturing a complete product such as AEPONYX is a smart move.